Overview

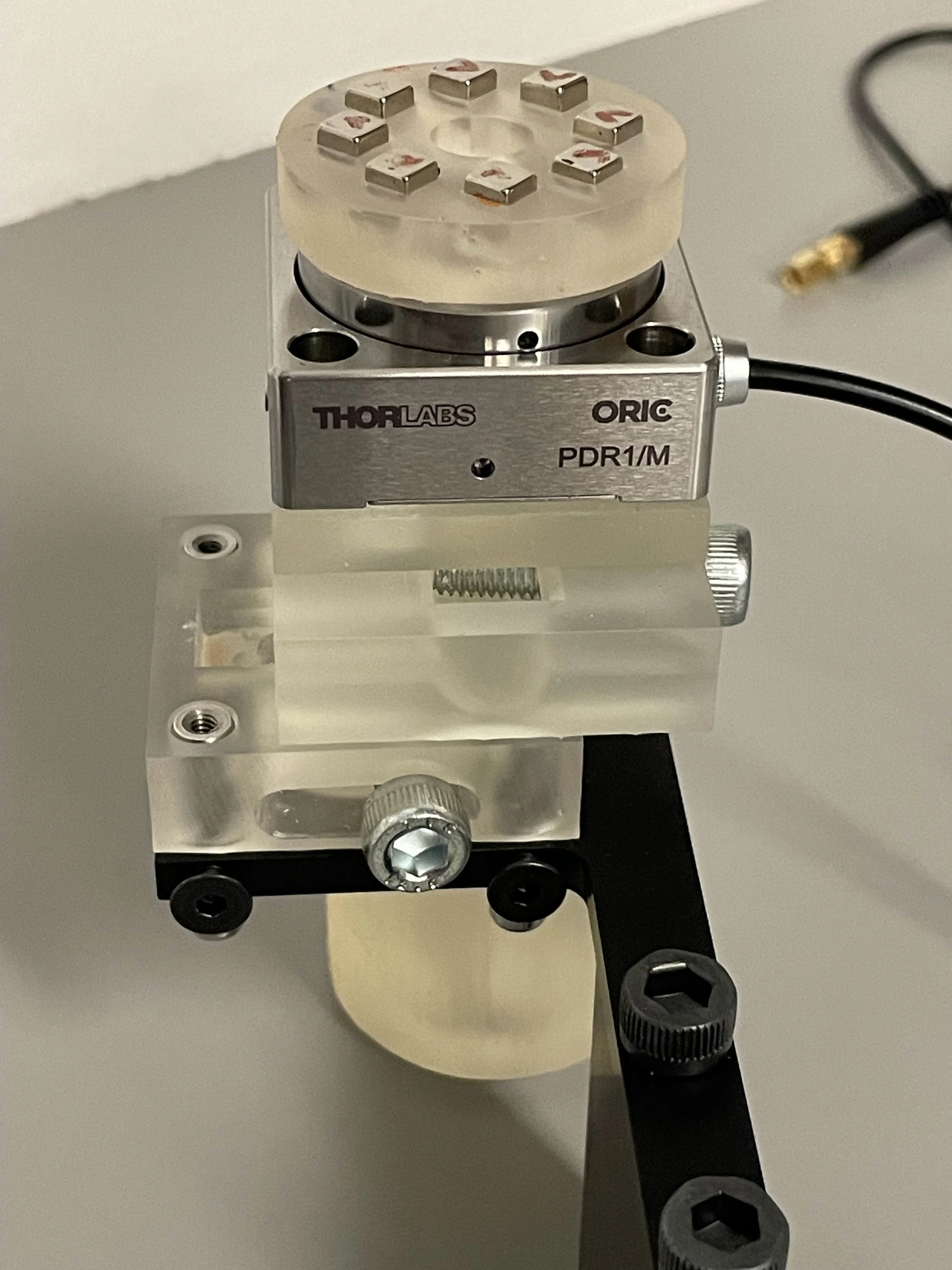

As part of a research project on magnetic droplet manipulation, I designed and optimized a 3D-printed magnetic actuator system to create a uniform and precisely positioned magnetic field.

Design Process

Mechanical Design & Optimization

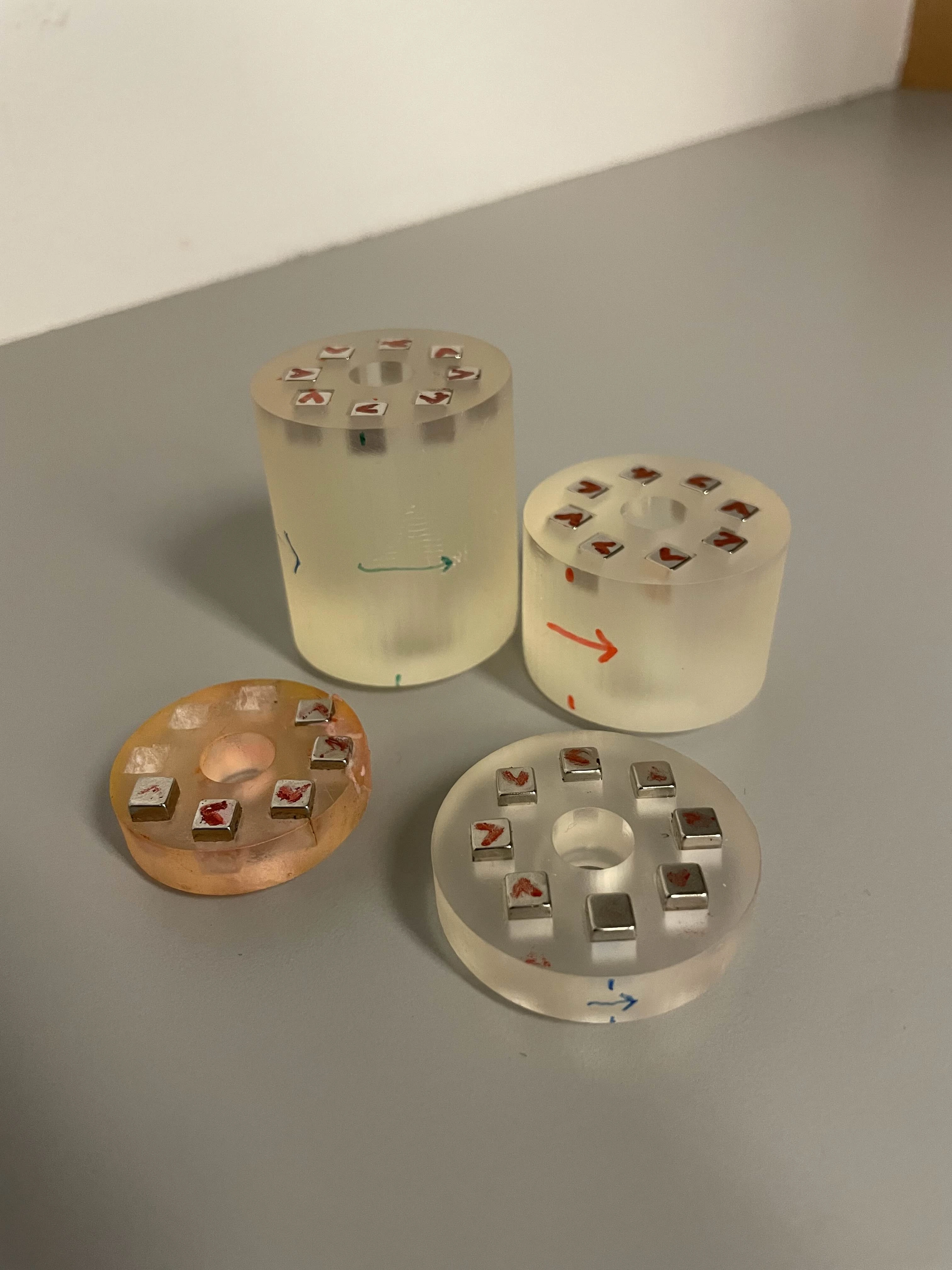

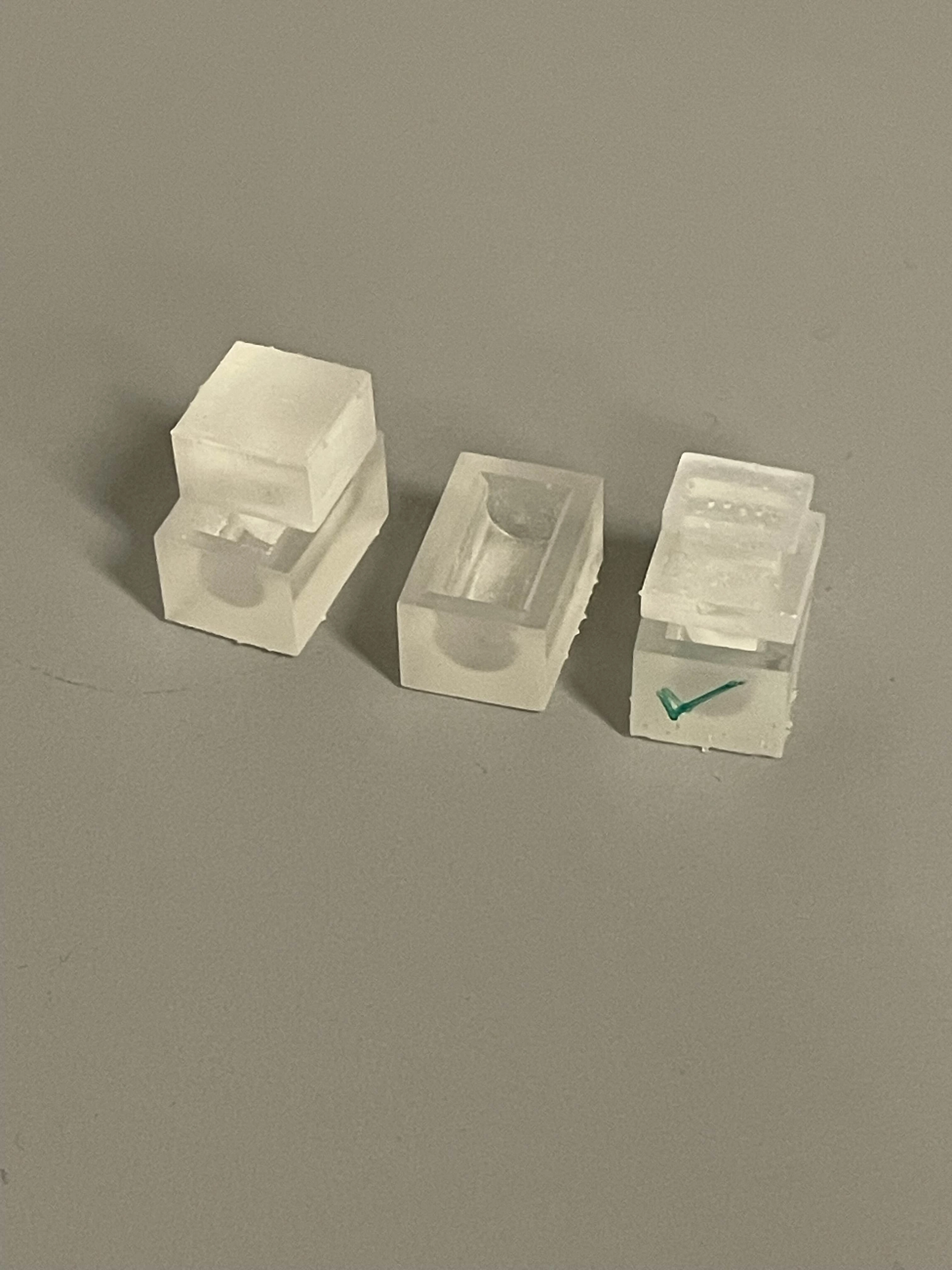

My work focused on the mechanical design, prototyping, and alignment calibration of the magnet holder. Through iterative design, I optimized parameters such as magnet fit, spacing, and holder height to maximize magnetic force without structural failure.

Innovation

Ball-and-Joint Adjustment Mechanism

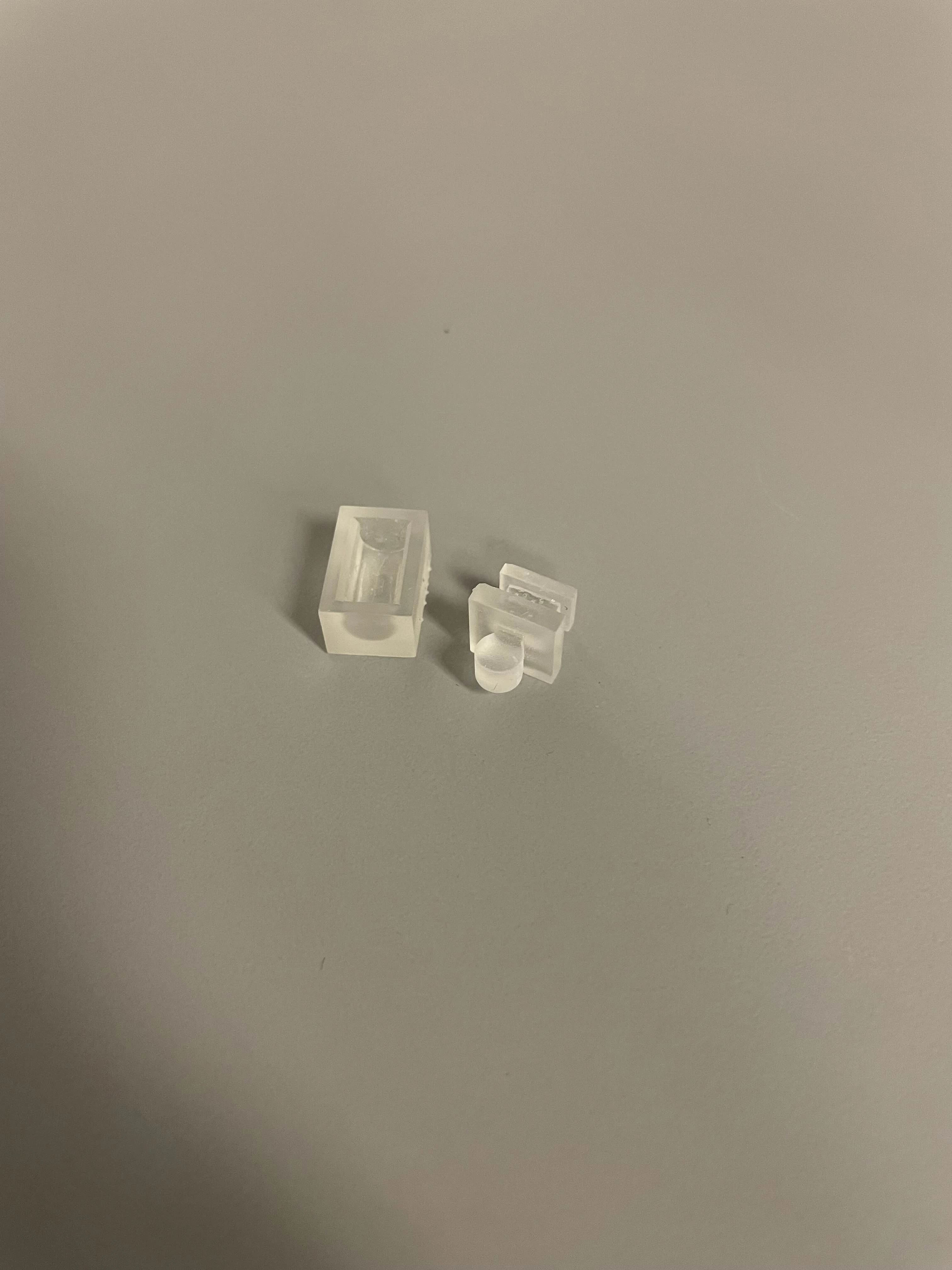

When initial tests revealed misalignment between the magnetic field and the optical axis, I developed a ball-and-joint adjustment mechanism that enabled controlled displacement and locking in both the x and y directions. This design allowed the magnetic field to be centered precisely under the sample and objective, improving the system's experimental accuracy.

Key Learnings

Skills Developed

- Mechanical prototyping

- Iterative design methodology

- Problem-solving in research contexts

- Precision alignment techniques

Project Impact

This project strengthened my skills in mechanical prototyping, iterative design, problem-solving, and precision alignment in research instrumentation, while contributing to improved experimental accuracy in magnetic droplet manipulation research.